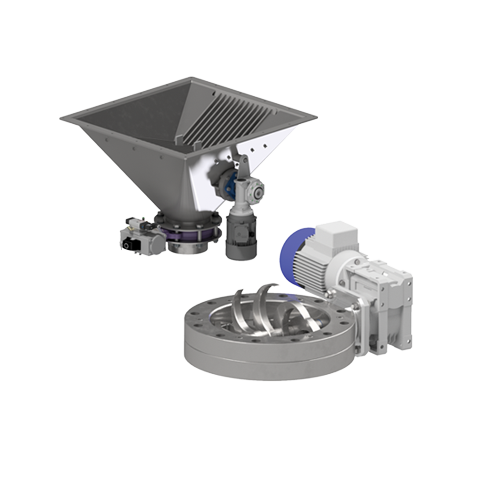

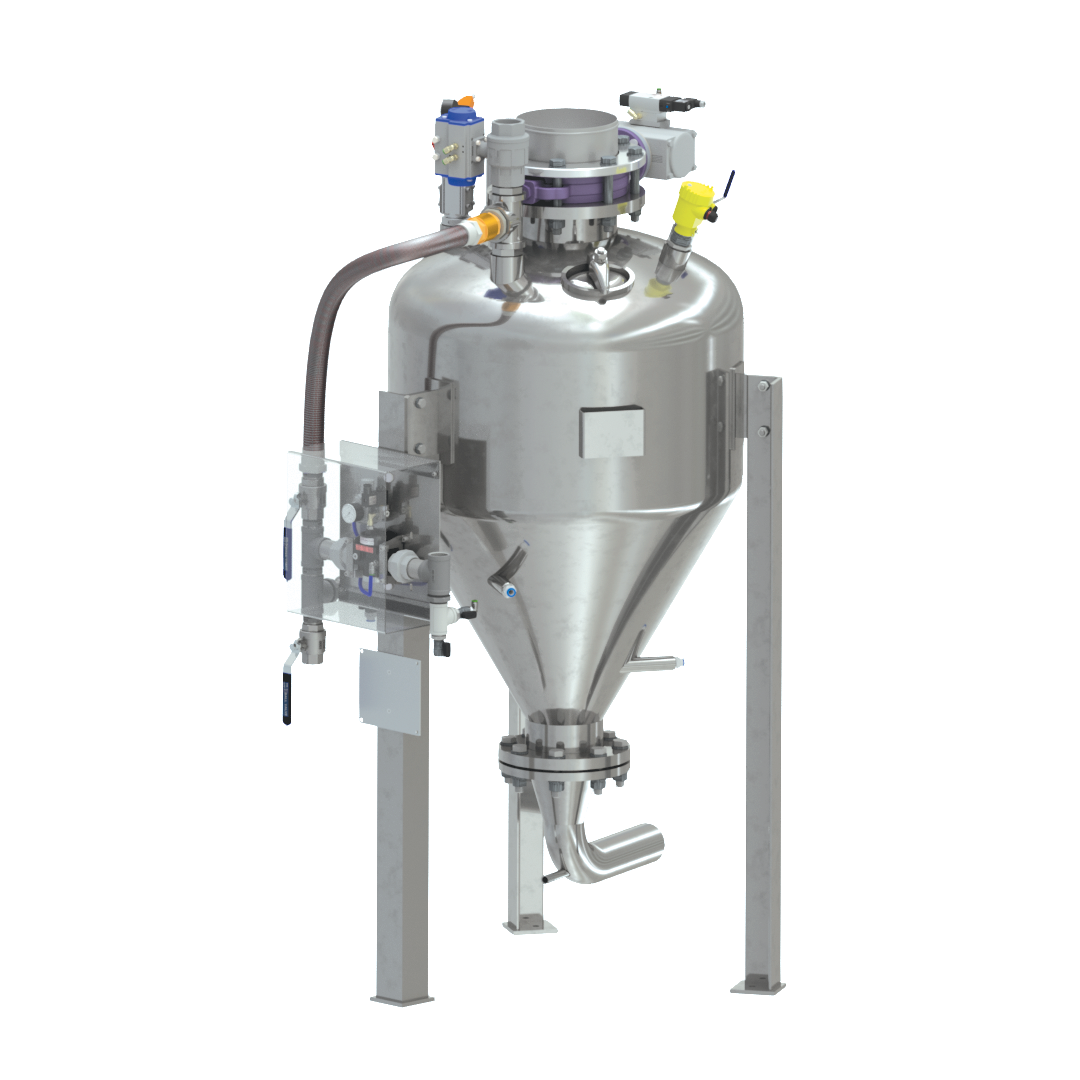

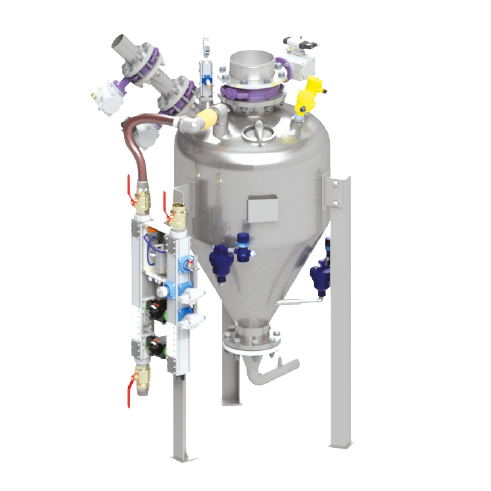

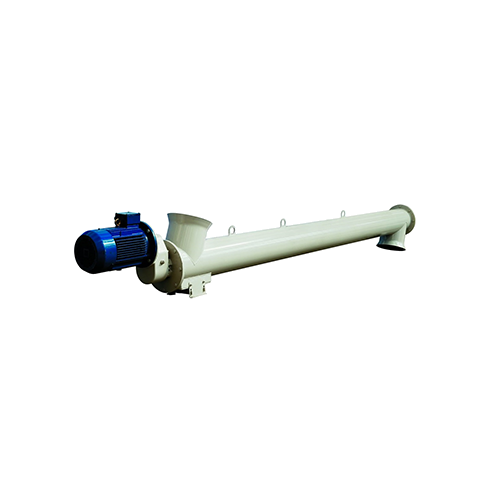

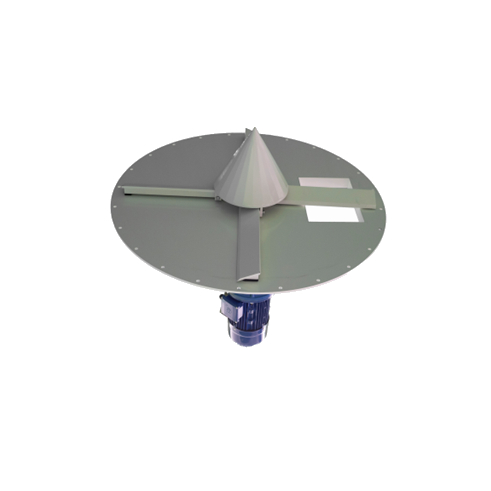

For handling and unloading particularly dusty materials that are particularly sticky, Air-Tec System uses flat-bottomed extractors.

The system is based on the ability of a rotating tool to move the product and bring it to an outlet on which a discharge valve or dosing screw can be installed.

Air-Tec System standards have different types of extractor tools, which are selected according to the application and the characteristics of the product to be processed.

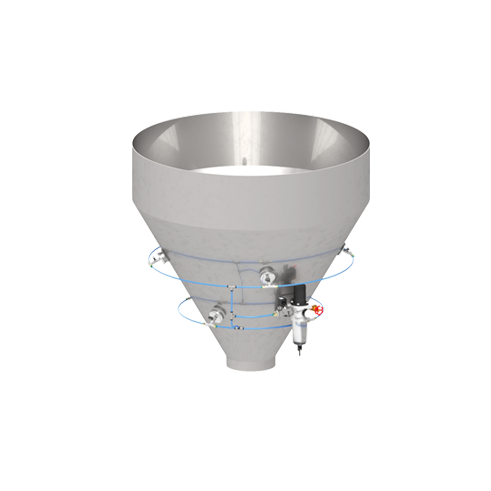

Air-Tec System offers extractors of various diameters, which can also be equipped with a containment hopper designed with specific geometries to ensure product descent.

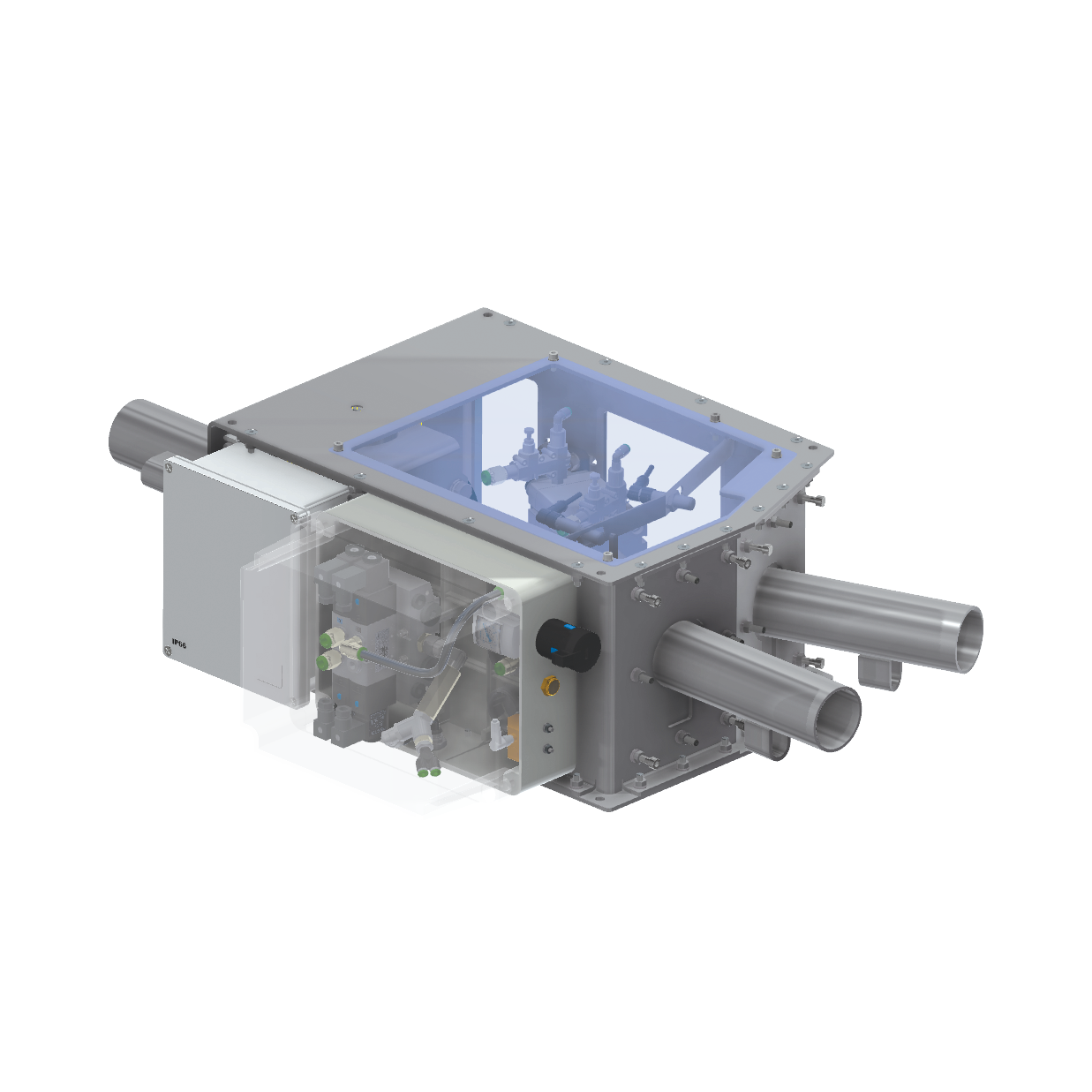

For handling and unloading particularly dusty materials that are particularly sticky, Air-Tec System uses flat-bottomed extractors.

The system is based on the ability of a rotating tool to move the product and bring it to an outlet on which a discharge valve or dosing screw can be installed.

Air-Tec System standards have different types of extractor tools, which are selected according to the application and the characteristics of the product to be processed.

Air-Tec System offers extractors of various diameters, which can also be equipped with a containment hopper designed with specific geometries to ensure product descent.