Compressors and

pump

Hook pumps, side channel pumps and blowers represent three different options in the field of pneumatic conveying, each with unique characteristics and specific applications.

The choice between them will depend on the specific requirements of the application, including the type of material to be conveyed, the required air flow rate and the pressure or vacuum needed.

COMPLETION OF INSTALLATIONS

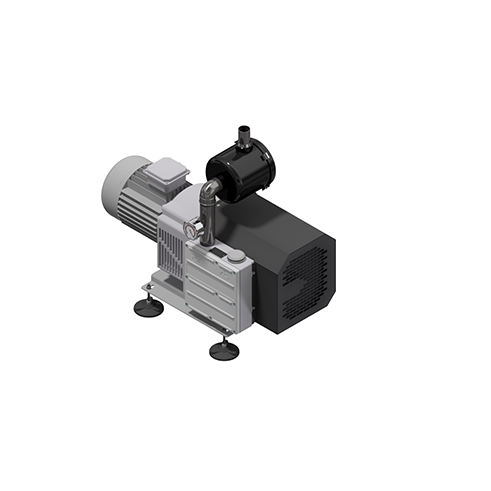

Hook pumps

Principle of Operation: Hook pumps are rotary devices that use two or more lobes or hooks to compress and move air or gas. These lobes move in a synchronised manner, creating sealed chambers within the pump. When the lobes separate, air is sucked into the chamber, while when they move closer together, air is compressed and pushed through the system.

Advantages: Hook pumps offer high energy efficiency and are capable of generating a very deep vacuum or significant pressure, depending on requirements. They are often used in industrial applications that require a high level of reliability and consistent performance.

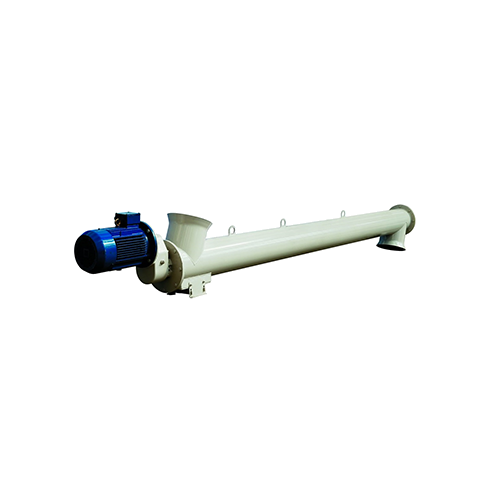

COMPLETION OF INSTALLATIONS

Side channel pumps

Principle of Operation: Side channel pumps are rotary vane devices with a spiral-shaped side channel. This side channel creates airflow in a radial direction. When the rotor turns, air is sucked in along the side channel and pushed towards the outlet.

Advantages: Side channel pumps are known for their reliability, ability to handle solid particles and resistance to wear. They can operate continuously without heating up and are suitable for vacuum and moderate pressure applications.

COMPLETION OF INSTALLATIONS

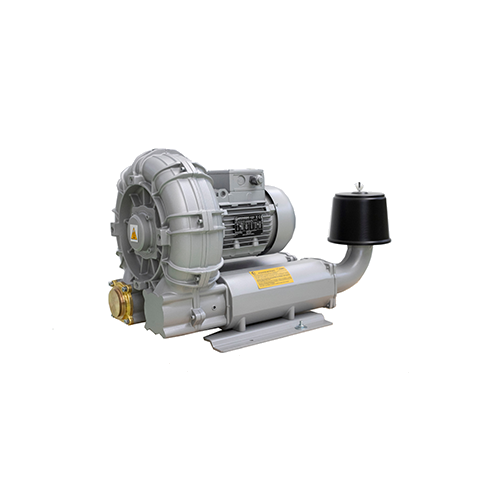

Blower

Principle of Operation: Blowers are lobe or screw-type volumetric devices. They generate a pulsating air flow inside a sealed chamber. The lobes or screws move in the opposite direction, compressing and expanding the air in a cyclic manner.

Advantages: Blowers are known for their ability to generate a constant air flow and are suitable for applications requiring a high air flow rate. They can handle variable loads and offer good energy efficiency.

Compressors and pump

Hook pumps, side channel pumps and blowers represent three different options in the field of pneumatic conveying, each with unique characteristics and specific applications.

The choice between them will depend on the specific requirements of the application, including the type of material to be conveyed, the required air flow rate and the pressure or vacuum needed.

COMPLETION OF INSTALLATIONS

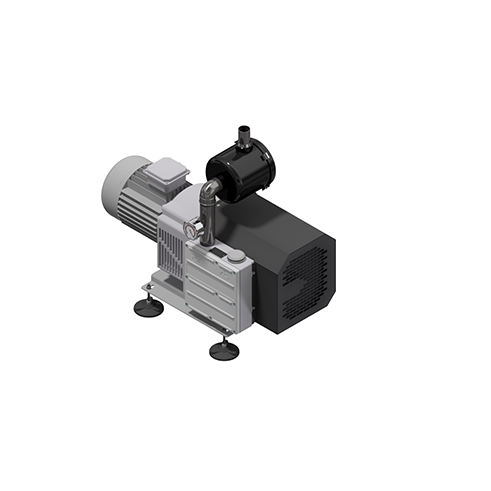

Hook pumps

Principle of Operation: Hook pumps are rotary devices that use two or more lobes or hooks to compress and move air or gas. These lobes move in a synchronised manner, creating sealed chambers within the pump. When the lobes separate, air is sucked into the chamber, while when they move closer together, air is compressed and pushed through the system.

Advantages: Hook pumps offer high energy efficiency and are capable of generating a very deep vacuum or significant pressure, depending on requirements. They are often used in industrial applications that require a high level of reliability and consistent performance.

COMPLETION OF INSTALLATIONS

Side channel pumps

Principle of Operation: Side channel pumps are rotary vane devices with a spiral-shaped side channel. This side channel creates airflow in a radial direction. When the rotor turns, air is sucked in along the side channel and pushed towards the outlet.

Advantages: Side channel pumps are known for their reliability, ability to handle solid particles and resistance to wear. They can operate continuously without heating up and are suitable for vacuum and moderate pressure applications.

COMPLETION OF INSTALLATIONS

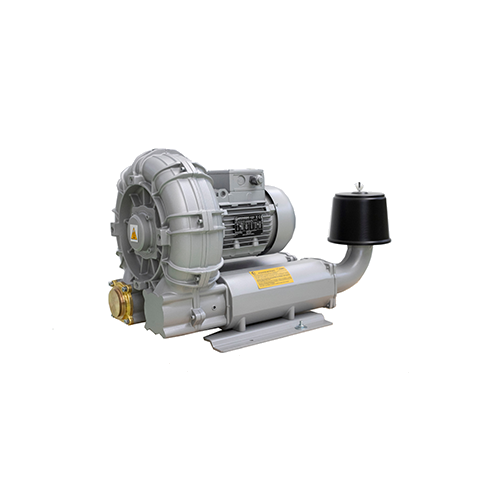

Blower

Principle of Operation: Blowers are lobe or screw-type volumetric devices. They generate a pulsating air flow inside a sealed chamber. The lobes or screws move in the opposite direction, compressing and expanding the air in a cyclic manner.

Advantages: Blowers are known for their ability to generate a constant air flow and are suitable for applications requiring a high air flow rate. They can handle variable loads and offer good energy efficiency.