Gravity Conveying Systems with Fluidized Motion

How to handle large quantities of materials at a low cost.

Most of the innovative conveying systems offer the possibility of being stopped and restarted during operation. This does not happen with many conventional mechanical systems and could generate considerable inconvenience in clearing pipelines, if this is necessary.

Therefore, for plants where a pipeline clearing phase is required, more innovative systems would be well worthwhile considering. These latter solutions offer further advantages, since they are capable of handling large quantities of materials with a reduced quantity of air. Consequently, operating costs are lower than other types of pneumatic transport.

Fluidized bed conveyor systems are generally not recognized as pneumatic conveying solutions because they use very low pressure air and the material does not flow through a pipeline. In any case they are not part of the mechanical transport systems. Their driving force is gravity so that they are able to operate only with an inclination downwards, although at a very low angle.

Air-assisted gravity transport: the fluidized motion conveyors

In situations where the flow of a material is directed downwards, air-assisted gravity transport has numerous advantages compared with pneumatic conveying systems. The costs of the plants are significantly lower as well as the operating costs are lower; in addition, a wide range of materials can be handled at a very low speed.

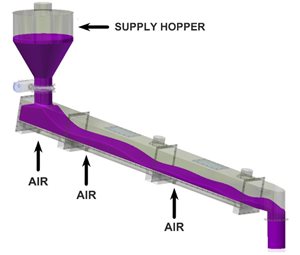

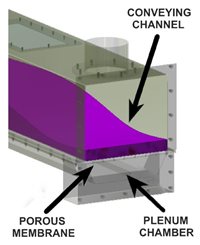

Gravity conveyors consist of a channel divided longitudinally by a continuous porous membrane on which the material flows, as shown in the figure above. The operation of these systems is based on the introduction of a small amount of low pressure air through the membrane.

The fluidized conveyors are able to move bulk material up to 100 meters and are suitable for flow rates up to 300 m3. In general, materials with a particle size from 40 to 500 µm and a density between 1400 and 5000 kg / m3, are the easiest to transport and will flow very smoothly down shallow slopes.

In our specialized, fully-equipped laboratory, we conduct complete and detailed powder analysis to verify the feasibility of a gravity conveyor system.

Are you looking for an air gravity conveying solution?

Visit the dedicated page!