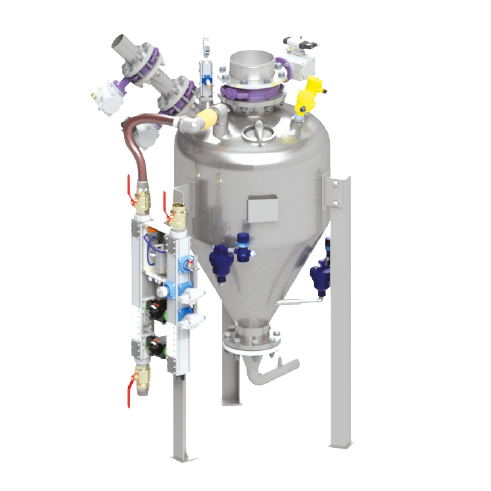

Dense phase

pneumatic conveying

Efficiency and benefits for different industrial needs.

Dense phase conveying is a solution for handling solid materials that is characterised by its remarkable efficiency and versatility. This technique is widely used in industrial settings and offers a number of key advantages for optimising production processes. In this article, we will explore dense phase conveying in more depth, its main characteristics, and the benefits it can bring to your industry.

What is Dense Phase Conveying?

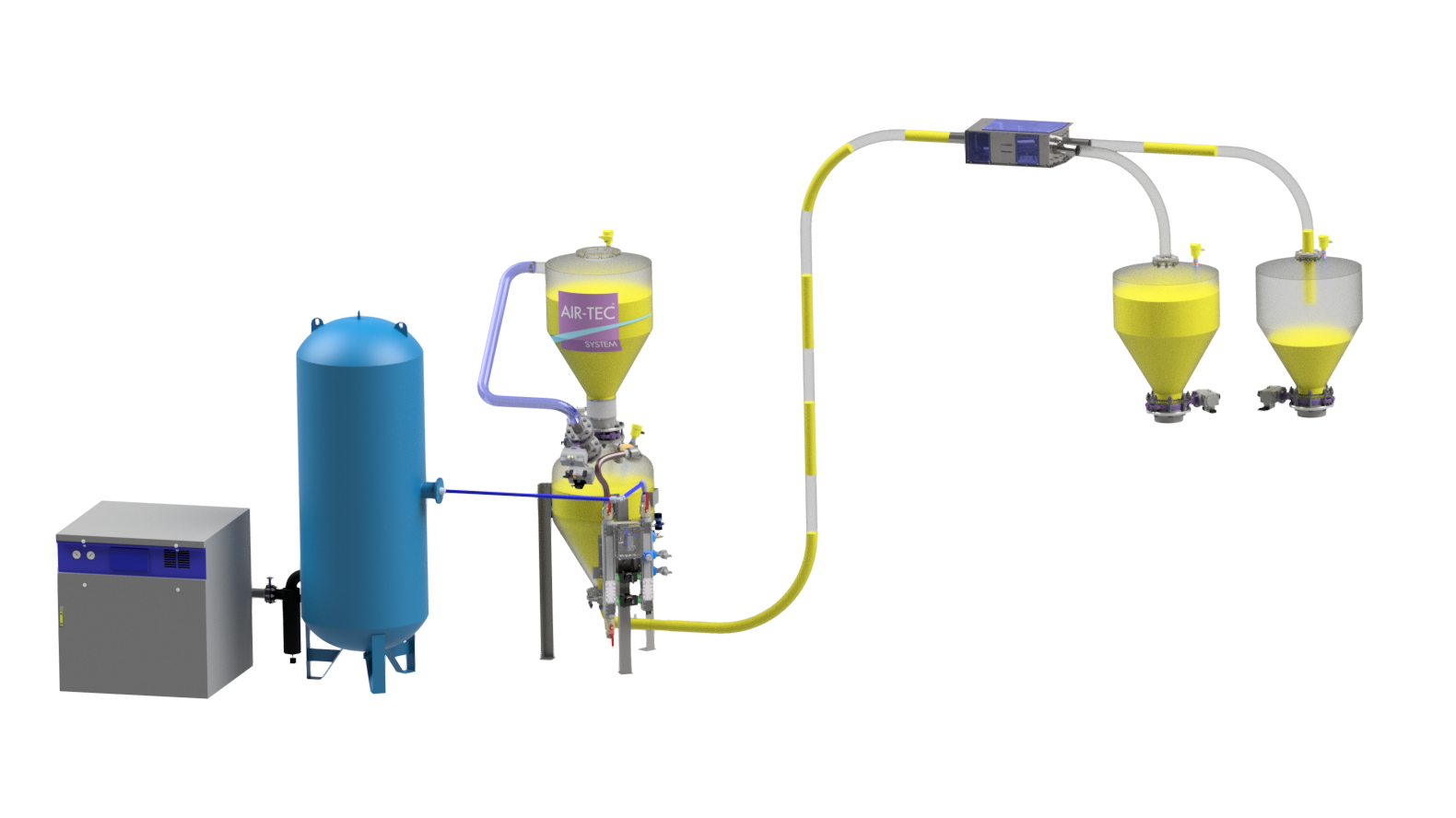

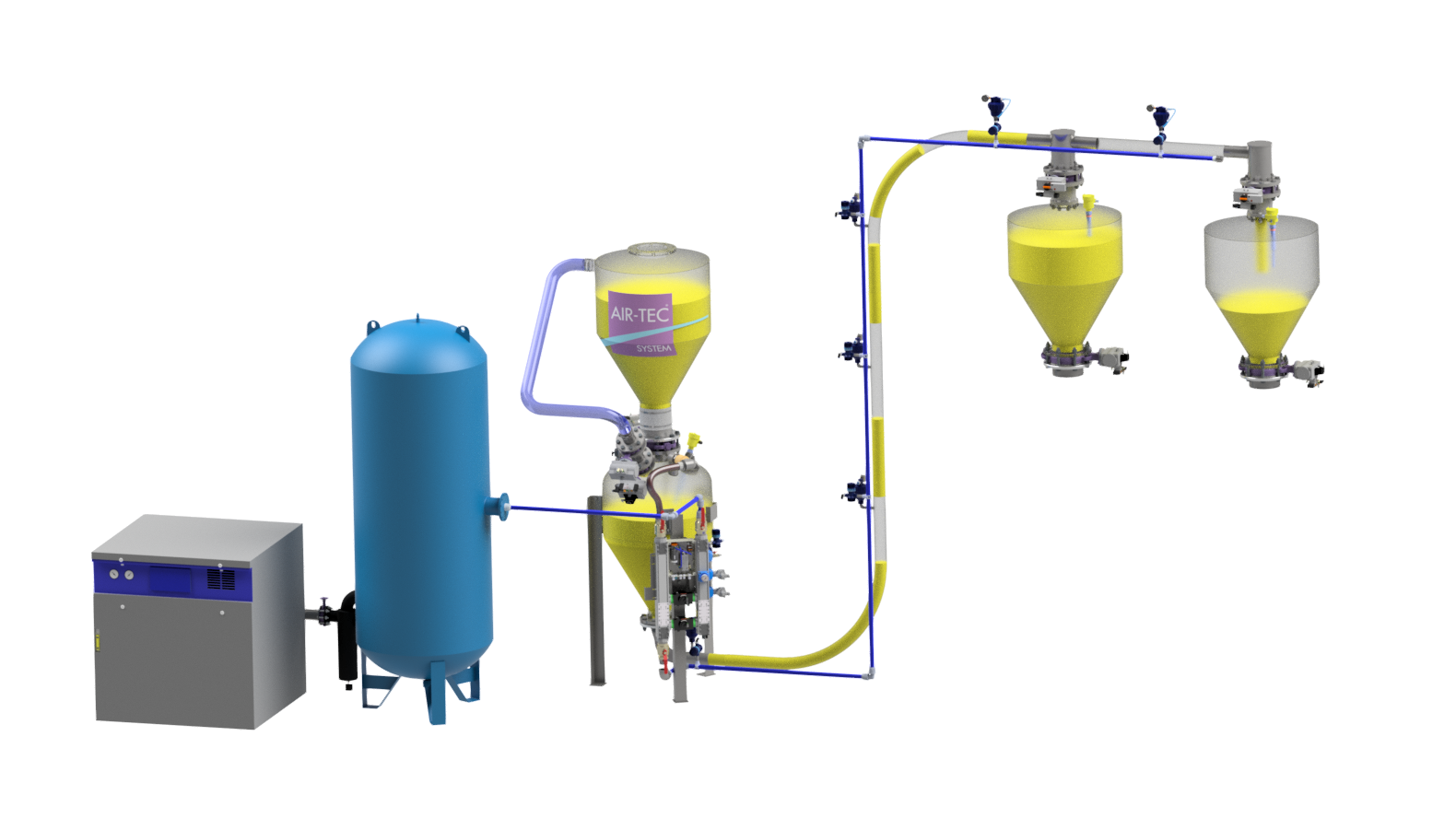

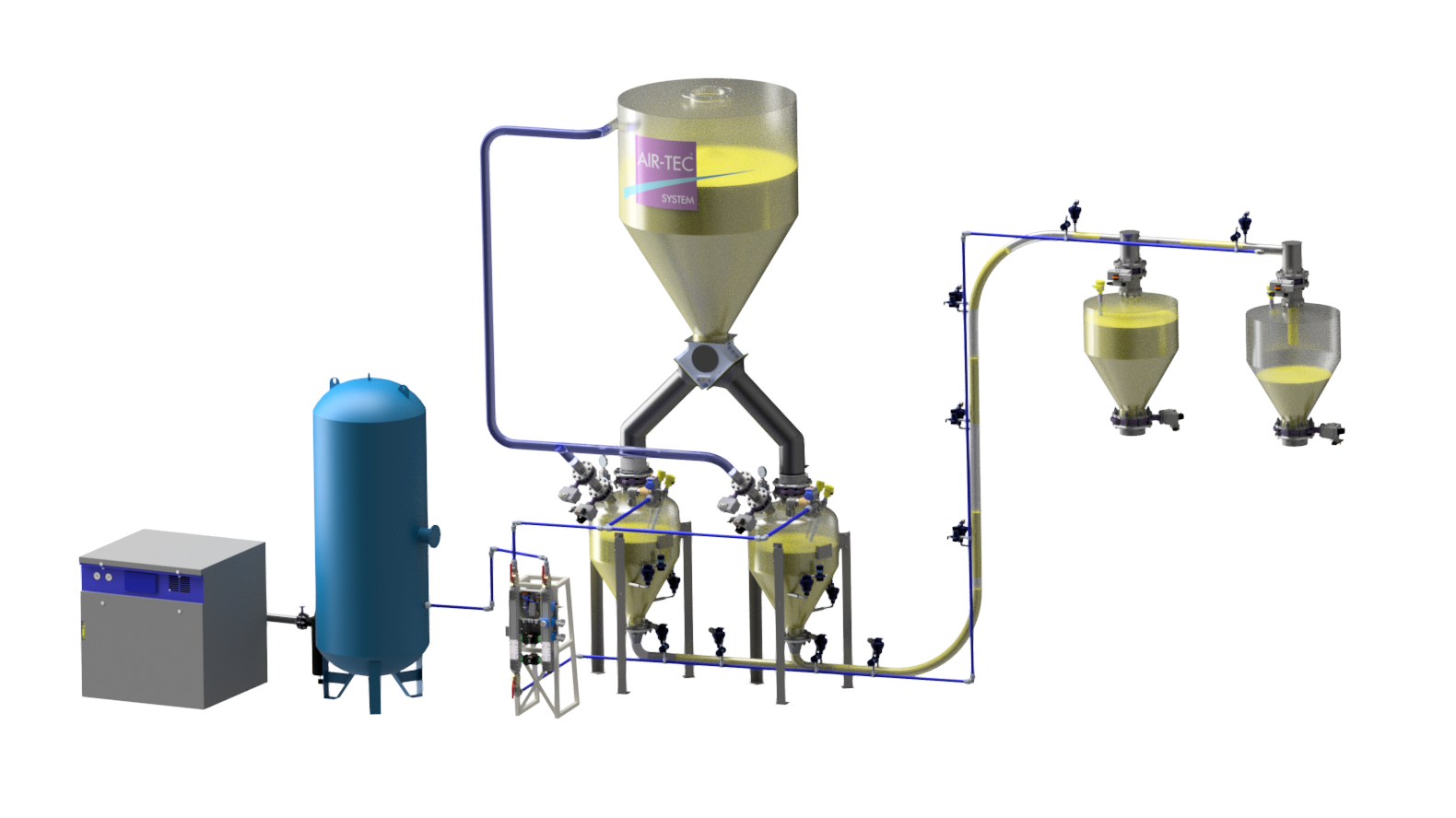

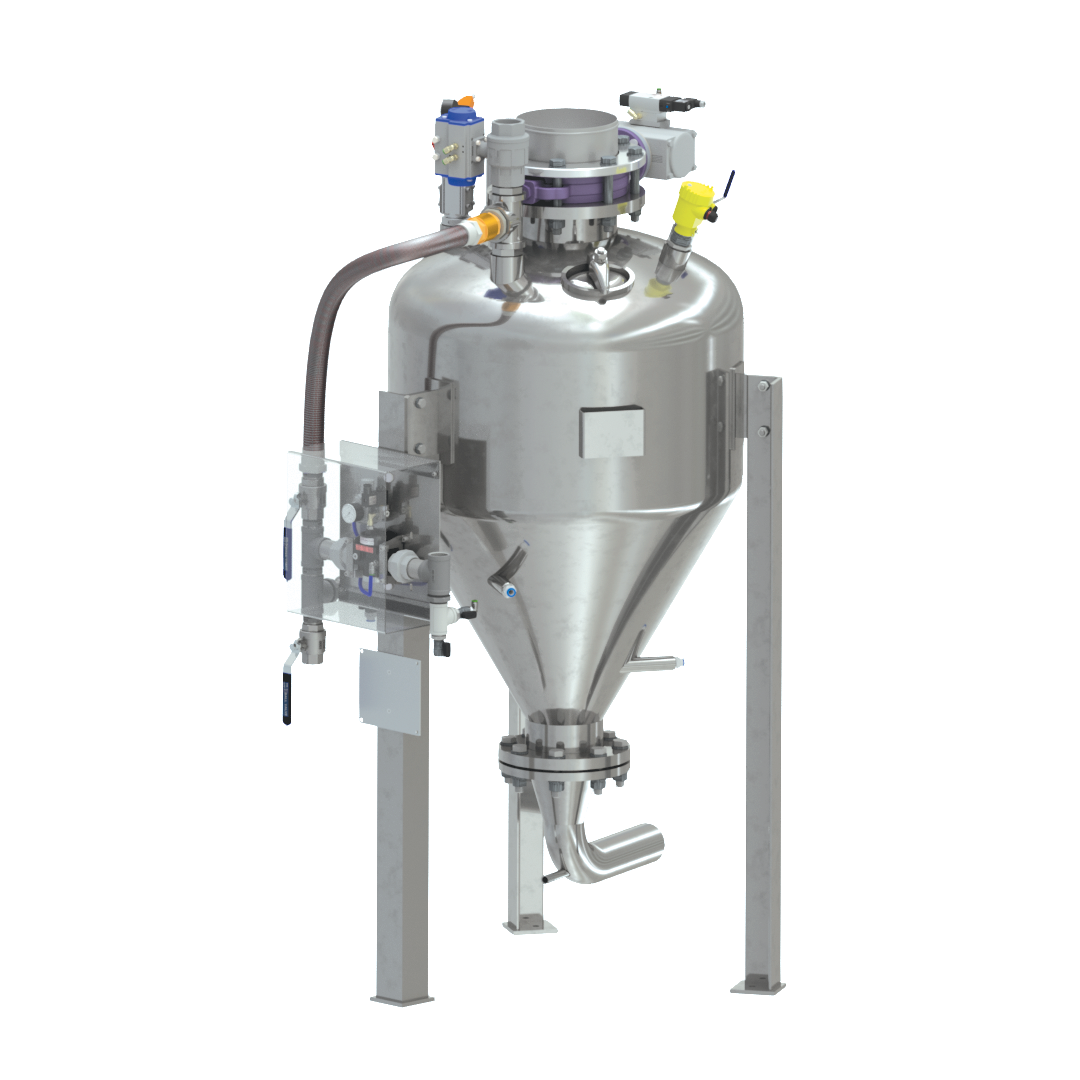

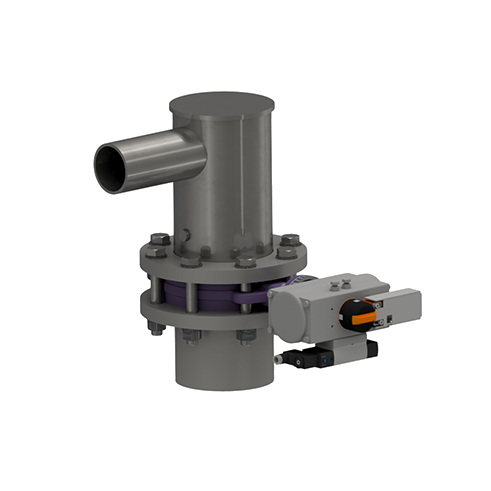

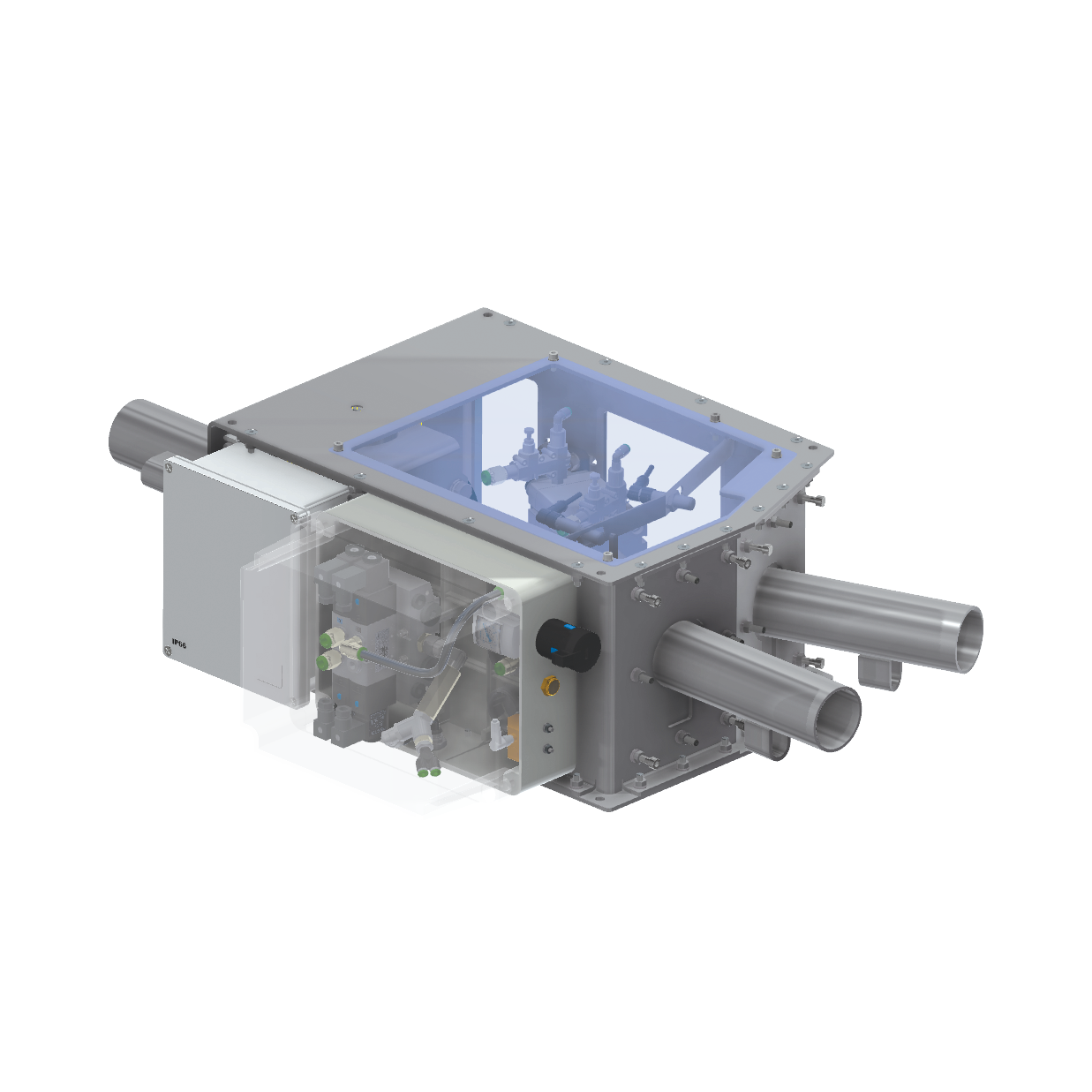

Dense phase conveying involves the handling of solid or particulate materials within pipes through a process involving the use of conveyors or filling devices. These devices generate a plug of material that is pushed along the path by a transport fluid, ensuring the efficient and controlled movement of materials. Fluid pressure regulation allows the speed of the process to be controlled, offering flexibility in applications.

The Advantages of Dense Phase Conveying:

- Energy Efficiency: Dense phase conveying is known for its energy efficiency, enabling the transport of large quantities of materials with reduced energy consumption.

- Protection of Sensitive Materials: Due to the low speeds involved, this method minimises breakage or wear of the delicate materials, preserving their quality.

- Adaptability to mixtures: The plug formation of the materials inside the pipes helps to keep the mixtures intact during transport.

- Precise Process Control: Pressure regulation allows the transport to be adapted to the specific requirements of the application and environmental conditions.