Dense phase pneumatic conveying

Full pipeline

system

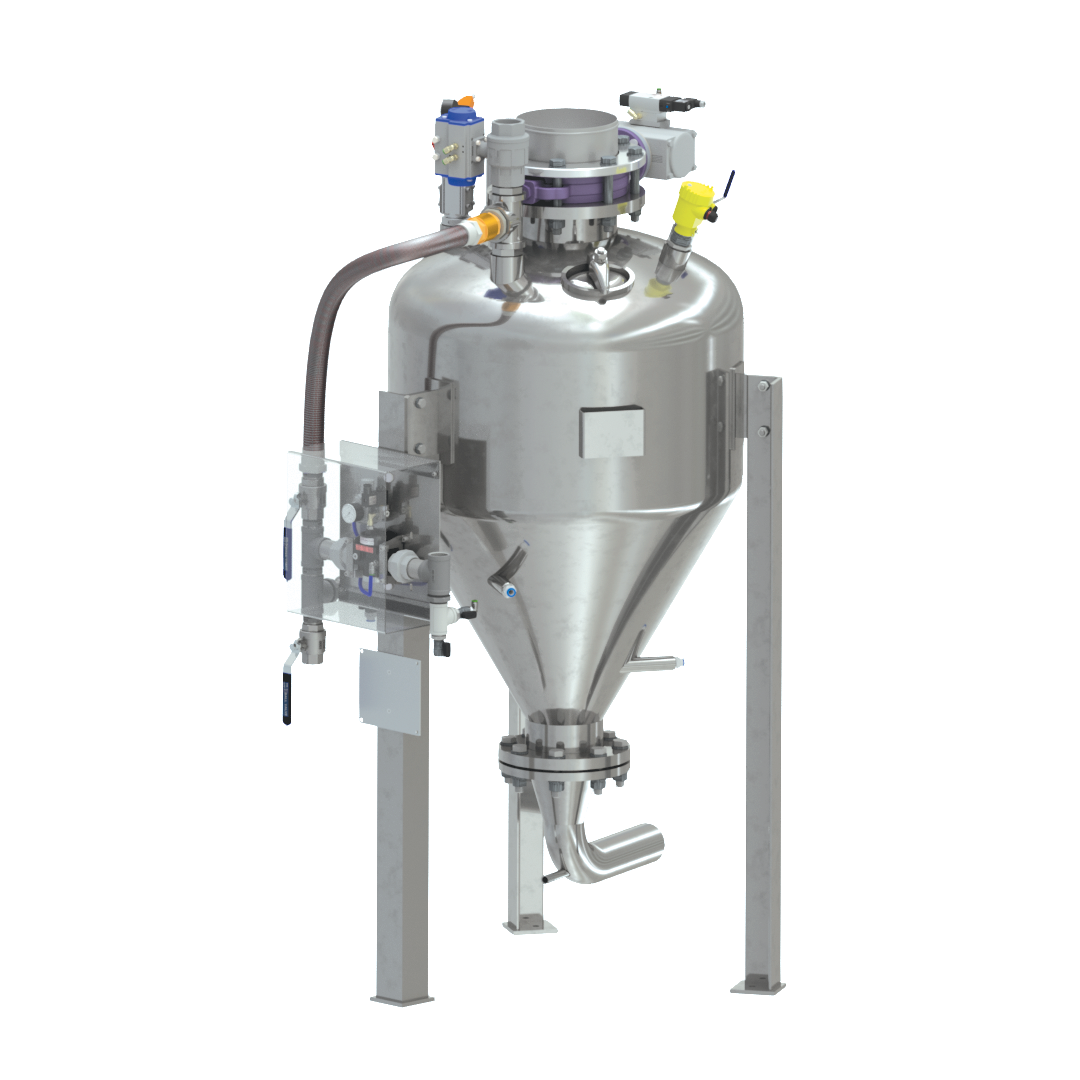

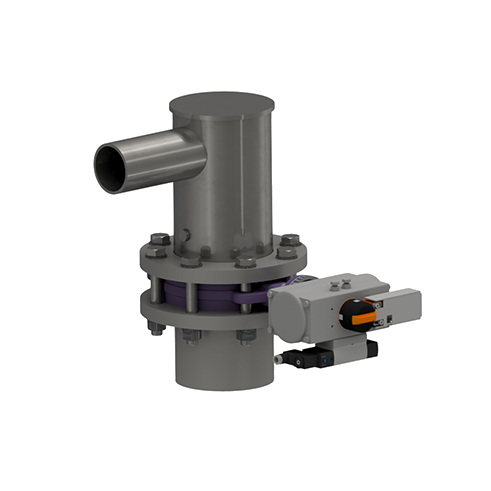

Full pipeline pneumatic conveying is an innovative method in which pressure is managed by a PLC with a specially designed control programme to maintain constant speeds during handling.

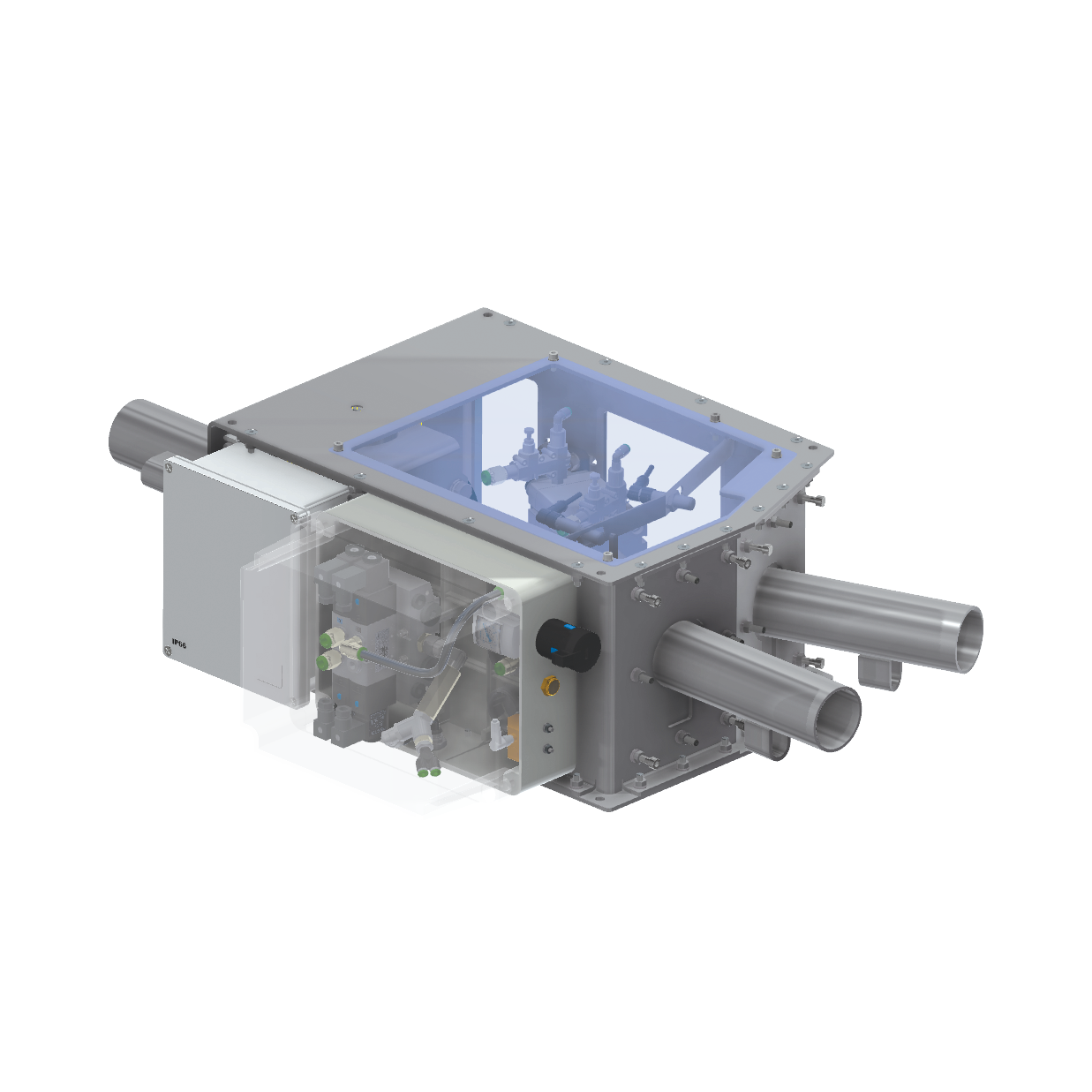

Conveying cycles take place with the tube full to achieve significant air and energy savings. The full pipeline method is used to handle fragile and abrasive materials over long distances.

The entire conveying line consists of two parallel pipes: one for transporting material to its destinations and one for feeding air into the pipe via boosters.

Some applications:

- conveying of fragile or abrasive products;

- conveying of products over long distances.

Dense phase pneumatic conveying

Full pipeline

system

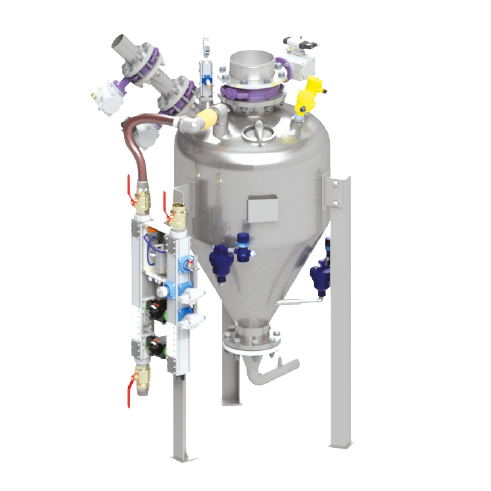

Full pipeline pneumatic conveying is an innovative method in which pressure is managed by a PLC with a specially designed control programme to maintain constant speeds during handling.

Conveying cycles take place with the tube full to achieve significant air and energy savings. The full pipeline method is used to handle fragile and abrasive materials over long distances.

The entire conveying line consists of two parallel pipes: one for transporting material to its destinations and one for feeding air into the pipe via boosters.

Some applications:

- conveying of fragile or abrasive products;

- conveying of products over long distances.