Pneumatic transport sizing

Know the parameters that contribute to the sizing of a pneumatic conveying system

Pneumatic transport sizing: find out the right technology for your product

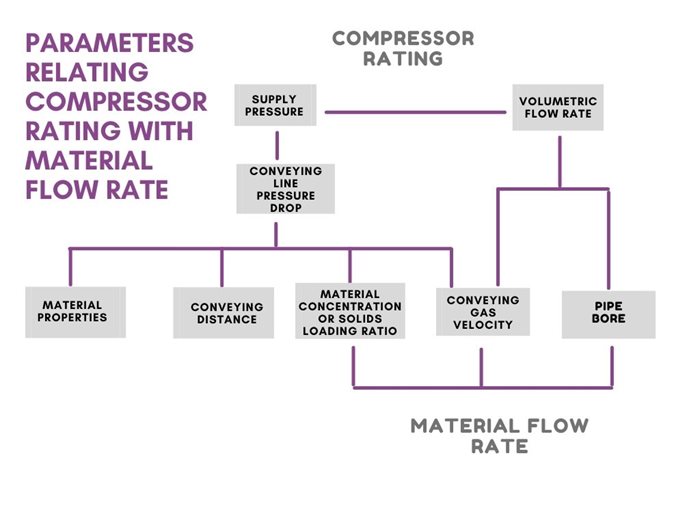

To select the best system for your needs, you should consider a number of factors including material properties, desired throughput and conveying distance.

Other factors to consider are for example air pressure, air flow and velocity.

Typical pressure values for dilute conveying systems are:

ΔP: from + 0,2 to + 0,8 bar for pressure systems

from -0,2 to – 0,5 bar for vacuum systems

Typical pressure values for dense phase pneumatic systems are higher, ranging between 0,5-5 bar.

Air flow, which is the amount of compressed air needed to obtain the speed for the conveying process, is affected by three factors:

- Material properties

- Conveying distance

- Throughput

- The first step in pneumatic system design is to determine the blend ratio (material kg/air kg), considering that air, at 20°C and at 1 bar pressure, has density of 1,22 kg/m³.

The formula is:

rp= product (kg) / air (kg)

where rp is the blend ratio.

The blend ratio can have different values: for dilute phase systems the maximum value is 8-9 (however, it is advised not to exceed 5-6); for dense phase systems the blend ratio is about 30 L of air per 1kg/product.