Why segregation of mixtures might be a problem

Powder stratification and blend prone to demixing

If you handle bulk materials with different physical and/or chemical properties, you might be familiar with segregation issues.

Whatever your industrial sector is (food industry, pharmaceutical, chemical, etc…), it is important that the mixture transported remains homogenous and uniform.

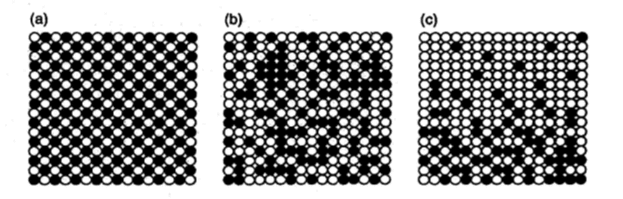

Taking a binary mixture as an example, we can have three degrees of blending:

- Perfect mixture

Every part of the mixture has the same pattern. This is theoretically possible but not achievable in practice (picture a).

- Random mixtures

The probability of finding a specific component at any point in the mixture is the same everywhere (picture b).

- Segregating mixture

The probability of finding a specific component varies depending on the different points in the mixture (picture c).

Therefore, you can understand why segregation is such a common issue when handling material mixtures. In many applications, it’s almost impossible to obtain a uniform and homogenous blend.

Dense phase pneumatic conveying can overcome efficiently this issue. Dense phase systems use approximately 30 litres of gas to move 1 kg of product but, due to the high pressure inside the pipeline (more than 1 barg), powders form compacted plugs which are then carried along the line. This does not allow fine particles to segregate from the others.

How to reduce the risk of segregation.

Laboratory tests should be performed to check if a blend is prone to demixing and to advise on precautions to adopt to avoid this issue.

We can carry out pneumatic transport tests at our facilities and we take several samples of material, before and after the transport. These samples are then put inside some 250 ml transparent jars (see picture above) and then checked.

Once we have excluded the chance that the powder can stratify, we can then measure the average bulk density at different heights, so that we can be more detailed about the risk of segregation.

We have tested more than 500 powders in our laboratories and we have come to the conclusion that only dense phase pneumatic conveying can avoid powder stratification.

Francesco Pozzi

Head of Air-Tec System Research and Development Department