PRODUCTS

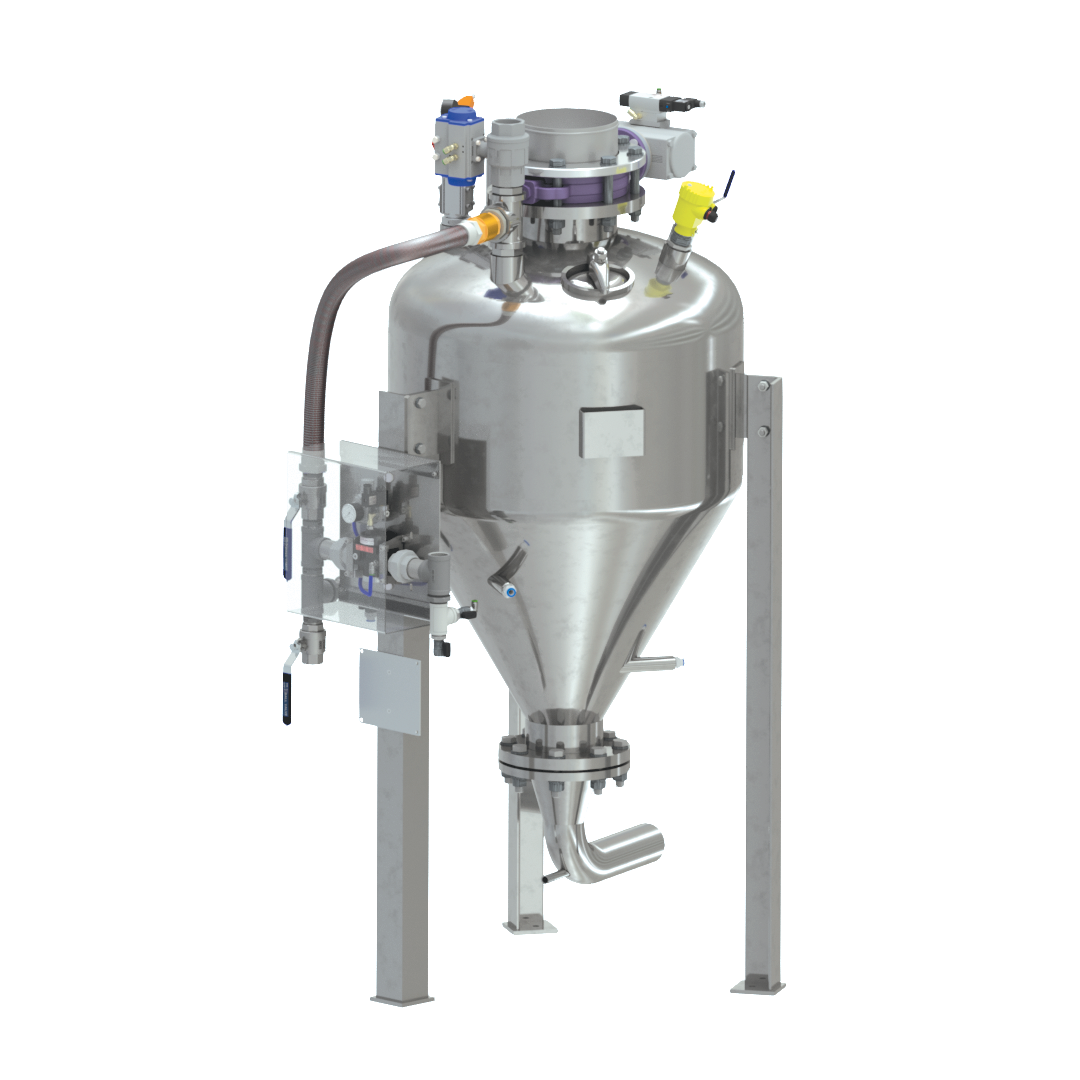

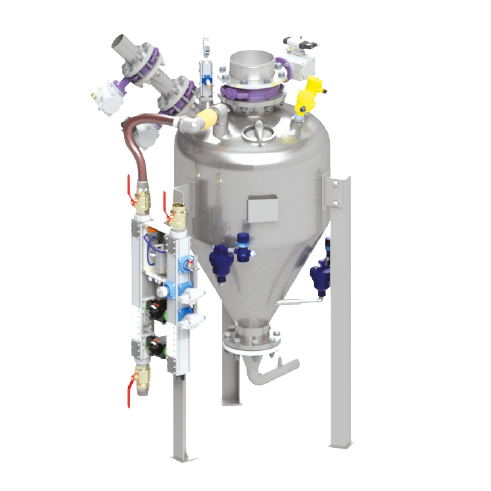

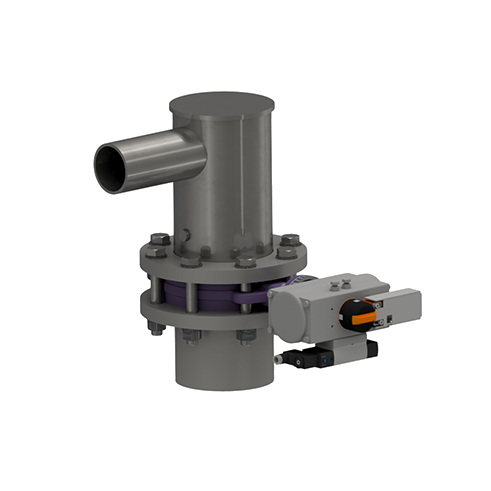

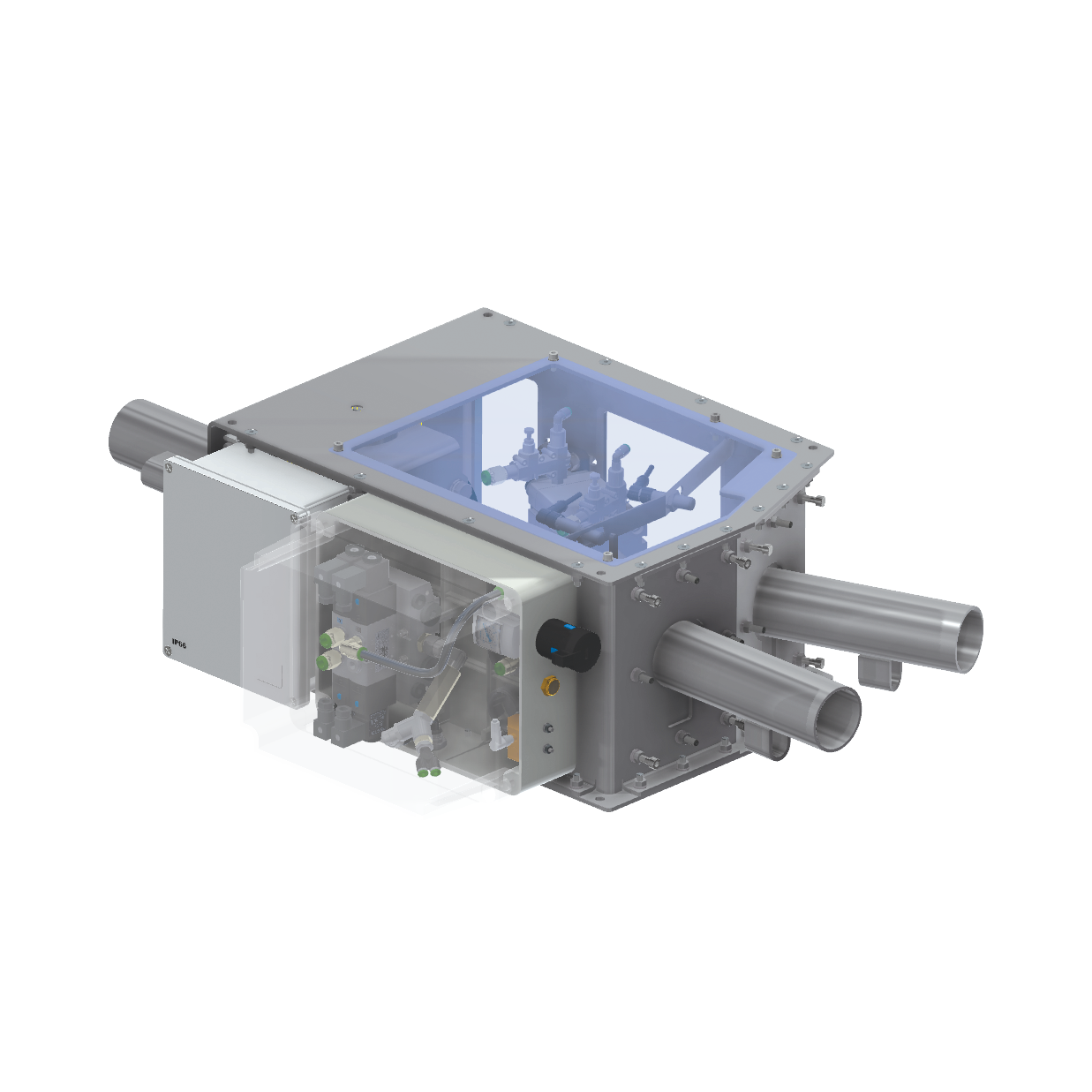

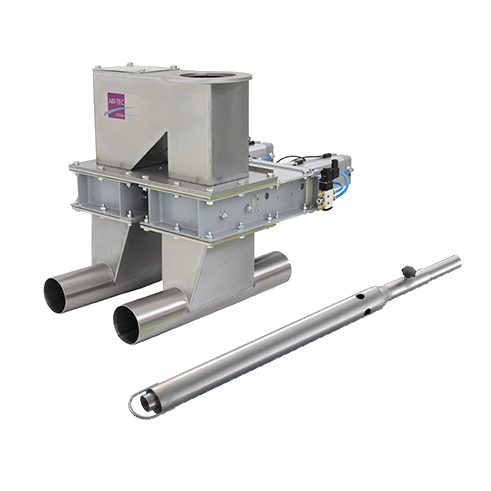

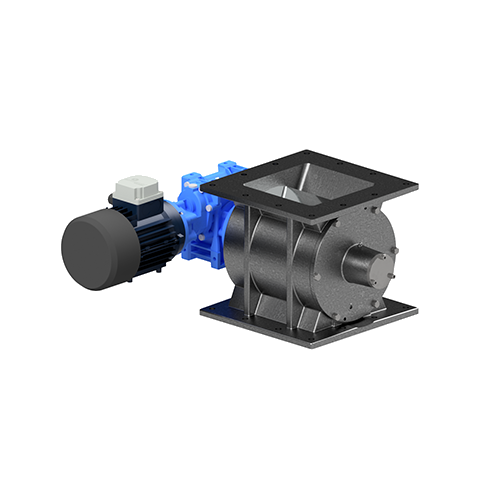

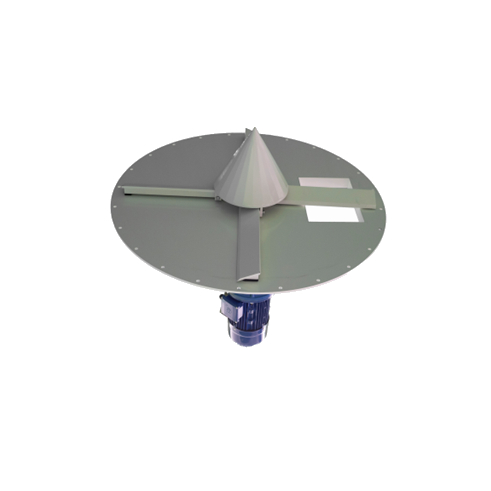

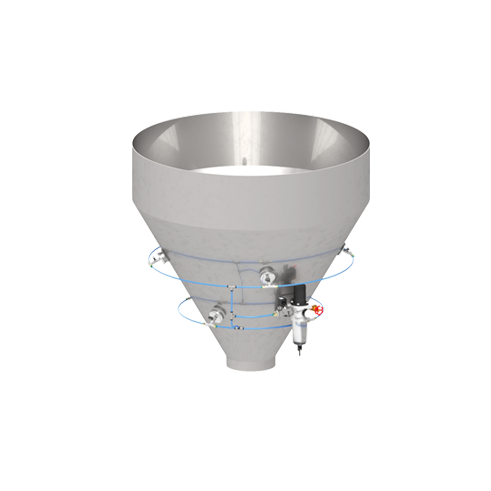

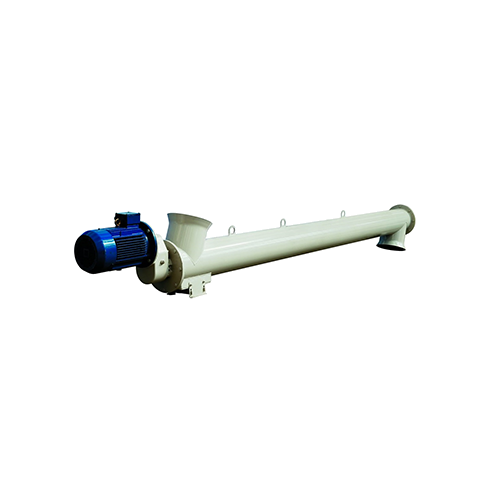

Air-Tec technologies and products

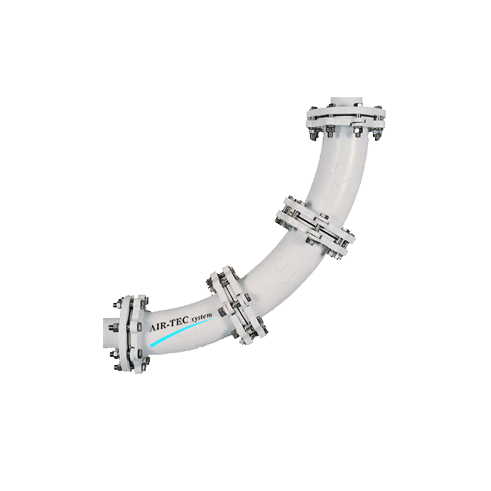

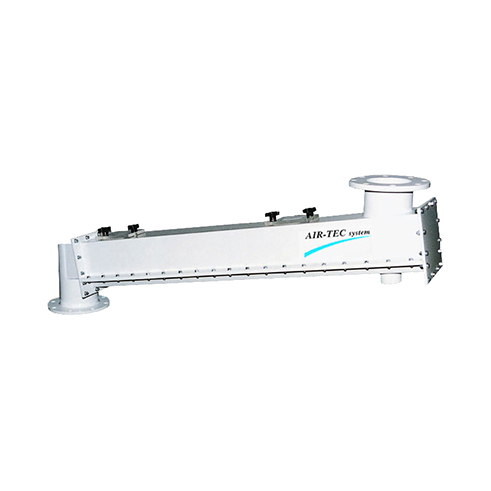

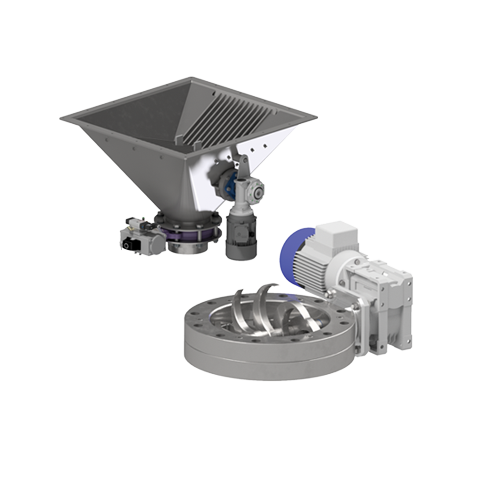

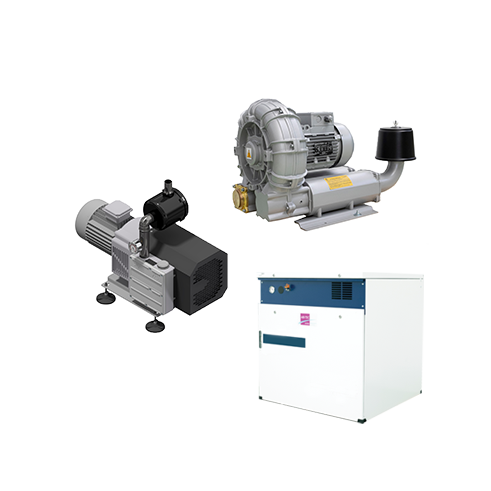

A leading manufacturer of pneumatic conveyors, Air-Tec System offers patented devices and customised solutions. From the dense to the dilute phase, we customise systems for you.

PRODUCTS

Air-Tec technologies and products

A leading manufacturer of pneumatic conveyors, Air-Tec System offers patented devices and customised solutions. From the dense to the dilute phase, we customise systems for you.

SERVICES

The Air-Tec World

From system design and installation to after-sales service. Turnkey solutions for every pneumatic conveying need.

TECHNICAL AND COMMERCIAL CONSULTANCY

The technical staff supports the customer during all phases of the project development, starting from an accurate study phase to the definition of every detail. Depending on the characteristics and quantity of material to be handled, the most suitable solution is proposed to meet the specific requirements.

LABORATORY ANALYSES AND TESTS ON PILOT SYSTEMS

Air-Tec System provides customers with a test area with pilot systems built on an industrial scale and a modern laboratory where material tests and analyses can be carried out. The results obtained will be useful for the subsequent design of new systems.

SERVICES

The Air-Tec World

From system design and installation to after-sales service. Turnkey solutions for every pneumatic conveying need.

TECHNICAL AND COMMERCIAL CONSULTANCY

The technical staff supports the customer during all phases of the project development, starting from an accurate study phase to the definition of every detail. Depending on the characteristics and quantity of material to be handled, the most suitable solution is proposed to meet the specific requirements.

LABORATORY ANALYSES AND TESTS ON PILOT SYSTEMS

Air-Tec System provides customers with a test area with pilot systems built on an industrial scale and a modern laboratory where material tests and analyses can be carried out. The results obtained will be useful for the subsequent design of new systems.

LABORATORY ANALYSES AND TESTS ON PILOT SYSTEMS

Air-Tec System provides customers with a test area with pilot systems built on an industrial scale and a modern laboratory where material tests and analyses can be carried out. The results obtained will be useful for the subsequent design of new systems.

DESIGN

The analysis and structural design of systems are aimed at satisfying the customer’s needs and guaranteeing the high quality of the services offered while respecting the agreed timeframe and compliance with current regulations. The system design includes: logical development, arrangement of components and machinery, design of transport lines, execution of structural calculations (where necessary), analysis of energy consumption.

SITE INSPECTIONS AND SURVEYS

In order to best plan the layout of machinery, components and structures, Air Tec System carries out preliminary inspections. The surveys precisely verify the available production spaces and how they interface with any existing systems.

SITE INSPECTIONS AND SURVEYS

In order to best plan the layout of machinery, components and structures, Air Tec System carries out preliminary inspections. The surveys precisely verify the available production spaces and how they interface with any existing systems.

PRODUCTION

Air-Tec System manufactures standard machines and customised projects using qualified in-house personnel and specific quality control procedures.

INSTALLATION

The installation of the system can be carried out entirely by Air-Tec System on a turnkey basis or directly by the customer, using the supervision or support of specialised technicians.

INSTALLATION

The installation of the system can be carried out entirely by Air-Tec System on a turnkey basis or directly by the customer, using the supervision or support of specialised technicians.

TESTING AND TRAINING

The commissioning of systems supplied by Air-Tec System is always guaranteed by experienced and qualified personnel working directly on site. All machines and systems are always complete with user and maintenance manuals.

SPARE PARTS AND SERVICE

Air-Tec System assists the customer during all phases of the installation, both construction and production, ensuring continuous after-sales support. The commitment and timeliness of the dedicated service technicians guarantee the operational continuity of the systems supplied.

SPARE PARTS AND SERVICE

Air-Tec System assists the customer during all phases of the installation, both construction and production, ensuring continuous after-sales support. The commitment and timeliness of the dedicated service technicians guarantee the operational continuity of the systems supplied.

DESIGN

The analysis and structural design of systems are aimed at satisfying the customer’s needs and guaranteeing the high quality of the services offered while respecting the agreed timeframe and compliance with current regulations. The system design includes: logical development, arrangement of components and machinery, design of transport lines, execution of structural calculations (where necessary), analysis of energy consumption.

SITE INSPECTIONS AND SURVEYS

In order to best plan the layout of machinery, components and structures, Air Tec System carries out preliminary inspections. The surveys precisely verify the available production spaces and how they interface with any existing systems.

PRODUCTION

Air-Tec System manufactures standard machines and customised projects using qualified in-house personnel and specific quality control procedures.

INSTALLATION

The installation of the system can be carried out entirely by Air-Tec System on a turnkey basis or directly by the customer, using the supervision or support of specialised technicians

TESTING AND TRAINING

The commissioning of systems supplied by Air-Tec System is always guaranteed by experienced and qualified personnel working directly on site. All machines and systems are always complete with user and maintenance manuals.

SPARE PARTS AND SERVICE

Air-Tec System assists the customer during all phases of the installation, both construction and production, ensuring continuous after-sales support. The commitment and timeliness of the dedicated service technicians guarantee the operational continuity of the systems supplied.

AIR-TEC

Who has

chosen us

Reliable experience and advanced solutions: discover our customers’ references that attest to our expertise and their satisfaction

AIR-TEC

Who has chosen us

Reliable experience and advanced solutions: discover our customers’ references that attest to our expertise and their satisfaction

AIR-TEC

Focus On

Discover the latest innovations in the world of pneumatic conveying with our Air-Tec System blog. Stay up-to-date on industry trends and stay connected with us for fresh news and insights. Join us on the journey of technological evolution

AIR-TEC

Focus On

Discover the latest innovations in the world of pneumatic conveying with our Air-Tec System blog. Stay up-to-date on industry trends and stay connected with us for fresh news and insights. Join us on the journey of technological evolution